Fire dampers, Mechanical Air handling & stair pressurisation systems

CoralAir provide specialist Fire Damper Installation & certification service directly to Building owners and Strata managers, where we work alongside the mangers to ensure passive fire compliance in relation to mechanical, intumescent and smoke dampers.

We further provide supporting technical advice to support

Buildings require fire safety certification annually. CoralAir specializes in the inspection and assessment of passive fire systems, with a dedicated team that can be deployed to professionally review and audit any building in the greater Sydney and Wollongong areas

The benefit to clients through entering into a fire dampers inspection service agreement is that they can fully utilize the expert knowledge our auditors have of each site. Typically, we assign one of our auditors to specific buildings, however, our proprietary audit software allows for our internal team to share site knowledge and tap into technical skills as required, ensuring continuity of relationship regardless of which member of our team attends the site.

Clients also benefit from the development of passive fire asset registers that can be used for overall building risk assessment and longer-term assurance of legislative compliance requirements.

Fire Dampers can be automated but typically there are four mechanical types activated by a fusible thermal link. The types of fire dampers are Curtain, Single Blade, Multi Blade, and Ceiling. As part of the building owner’s fire safety statement, you are required to test 20% per year (AS1851) so you effectively test the functionality of all Fire Dampers in your building over a five-year period.

A new development in Fire Dampers is Intumescent Fire Dampers. These act by expanding mechanically under heat. As they are a mesh or slat shape, they are not typically used in fan-forced ducts. They still need to be accessible for inspection and potentially cleaning.

CoralAir has perfected its Audit processes to facilitate efficient and accurate data capture with the additional ability to generate appropriate reports and fire damper inspection certificates.

Fire damper inspection certification is provided as appropriate to the inspection results. All our inspection certifications are kept on record in our system and will be provided to our clients upon request.

As part of our audit/review process, any substandard items are clearly identified with photos along with written notations for non-compliance. CoralAir will also provide a base quote cost of any rectifications referencing each defect.

Providing these reports after fire damper inspection provides our clients complete transparency to ensure a clear understanding of issues and what is required to resolve them. CoralAir provides Passive Fire Asset Registers to many clients to assist minimize risk and ensure compliance through assessment against the passive fire asset register.

Contact CoralAir to discuss the development of your Mechanical Fire asset register at service@coralair.com.au

Ventilation systems by their very nature will accumulate contamination the degree of which will be influenced by the quality of the incoming air, filtration, design, maintenance, and usage. Over time varying types of contamination will accumulate to levels which may detrimentally influence the quality of the supplied air and hence may affect the health of building users. Contaminant levels can build to such an extent that they provide the added risk of fire propagation.

The proper maintenance of a ventilation system is recognized as crucial to the health, economic and safe operation of occupied spaces. To ensure compliance with the Regulations and associated Approved Code of Practice from the Health and Safety Commission which states that all mechanical ventilation systems should be regularly and properly cleaned, tested, and maintained to ensure that they are kept clean and free from anything that may contaminate the air.

Fire dampers of the thermally released or motorized type shall be manufactured & installed in accordance with AS1682.1 & AS1682.2. Motorized dampers shall fail to the closed position by a thermally operated device located in the airstream. Damper closure retaining devices shall be incorporated.

Fire dampers of the intumescent type shall be manufactured to close under re conditions as a result of swelling of the intumescent material. Intumescent re dampers shall be tested in accordance with AS1530.4 with an extended fully closed-off period of 120s. Dampers shall also comply with the air leakage of AS1682.1 & installed in accordance with the relevant requirements of AS1682.2

• Check and ensure that the re-damper is in place, free from obstruction, and is capable of operation

• Check re-dampers, including casings and mounting angles for corrosion

• Check for signs of tampering or modification Maintenance should be completed at the specified intervals and scheduled in the project’s operation and maintenance manuals.

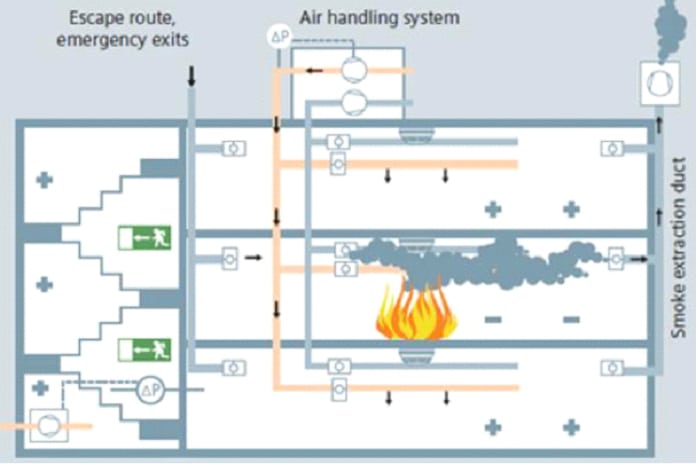

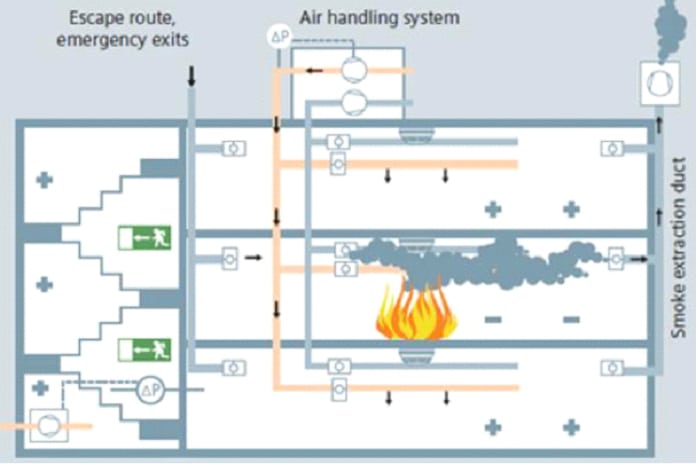

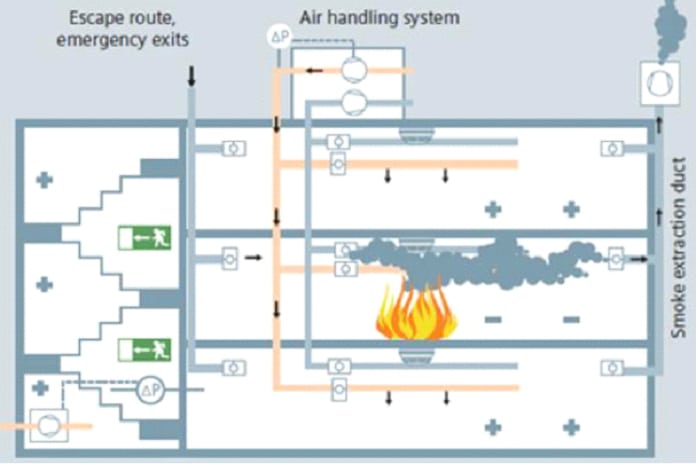

In general, a fire damper works when the heat from the fire causes the normal temperature of a room to rise to about 74°Celsius. The fusible link attached to the damper would then melt, causing the damper’s door to close. In rooms where the normal temperature of the room is consistently higher, a higher degree fusible link would be attached to the damper. These particular fusible links would melt at a temperature about 100° Celcius. There are two types of fire damper designs used to help prevent the spread of flames, a dynamic fire damper and a static fire damper.

Dynamic fire dampers are located in vertical barriers, where the HVAC system fan will stay on in the event of a fire. Because they are installed in vertical barriers, these particular fire dampers have a spring-loaded design. The spring-loaded design is where the doors of the damper have a spring like action when they are forced to shut.